Building 80m Inverted V Antenna for Restricted Space: VU2XTO Design

Caution: VU2XTO has informed that high power with a linear amplifier should not be delivered to this loaded coil dipole as it can result in heating of coils.

I can hardly squeeze in a 40m inverted V at my home. Still I wanted to try out 80m as some of my VU friends have started trying it out. I was told by an online DX friend that 80m is a very busy band in EU with DX even up to Middle East at night. I was active on 80m in 1980s with a horizontal dipole antenna tied on top of coconut trees at my parents’ home using a homebrew 3 x 807 AM/CW radio. VU2XTO design published in the Madras Amateur Radio Society Newsletter, Volume 26, Issue 2, July-September 2018 has the details of an 80m antenna for restricted spaces. What we need is a couple of 118 microhenry loading coils and about 14 m of insulated copper wire.

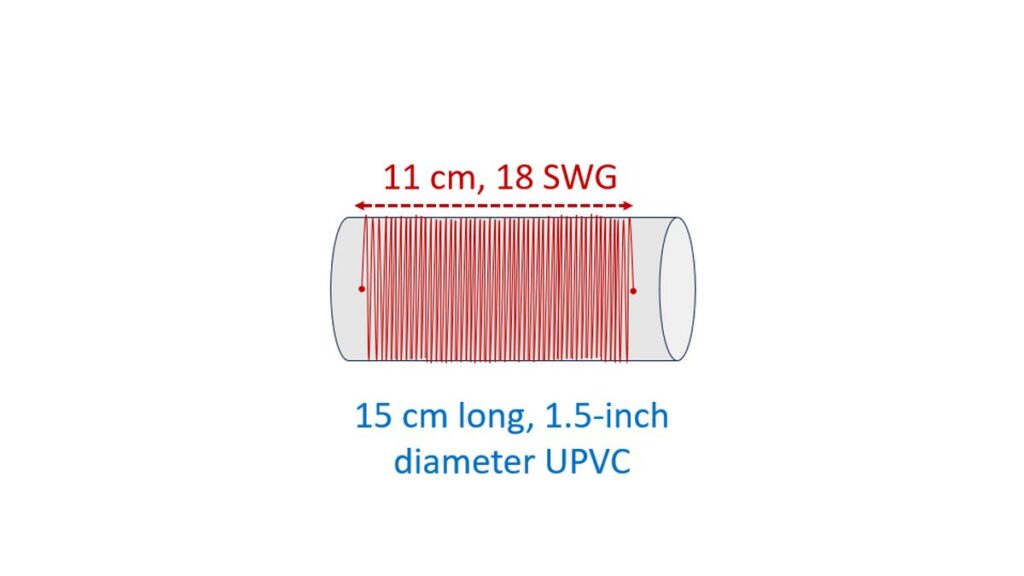

For the 118 microhenry coils, VU2XTO has suggested a 15cm UPVC former of 1.5 inch diameter and 18 SWG enamelled copper wire wound closely for a span of 11cm. It is basically an upgrade of a 20m antenna. So you need two pieces of insulated copper wire of 5m each from the feed point to the loading coils on either side. Beyond the loading coils we need another 2m each of insulated copper wire to make the antenna tune for 80m also. It has been suggested that we should first tune the 20m part of the antenna for 1:1 SWR and then tune the extra 80m part.

As I was not quite sure of how much enamelled copper wire I would need, I went and bought 500 gm of 18 SWG enamelled copper wire along with 15 m of 2.5 sq mm insulated copper wire, of which I will need 14m for the antenna. Remaining part may be kept as extra for tuning and tying the antenna, meant to be kept folded on either side. Now I have to cut pieces of PVC pipe which I have and wind the loading coils as well as cut the antenna, mount it and tune it. I would request my 40m ragchew friends to take it as a challenge and come up on the morning 80m net on 3.6 MHz at 7.15 am, at the earliest. Anyone with space for mounting a 40m antenna can easily mount this antenna for 80m, as the total length is less than that of the 40m antenna!

The 15m insulated copper wire was cut into two equal pieces so that each half would be 7.5m.

Then 2.25m pieces were cut off from each half so that 5.25m would remain. Coiled all the four pieces separately so that they would not get tangled together.

Checked the PVC pipes available here and found that this one would match the VU2XTO design of 1.5 inches.

Marked out the required 15cm portion using a scale and knife.

Then two 15cm pieces of PVC pipes were cut using a hack saw.

Two positions were marked on the PVC pipe pieces 11 cm apart for drilling holes. Two sizes of drill bits were used to drill holes, one each for the 18 SWG enamelled copper wire and the 2.5 sq mm insulated copper wire for antenna elements. Here you can see the enamelled copper wire and insulated copper wire passed through the newly drilled holes to make sure that they of sufficient diameter. Pliers were used to keep the pipe pieces steady while drilling. A small pit was made on the PVC pipes using the sharp edge of a screw driver before using the electrically operated hand drill, to avoid the drill bit slipping off from the PVC pipe.

This was the first loading coil which I made. It took about 20 minutes for me to wind it. As I do not have an inductance meter, I can only check the performance after mounting the antenna in full and testing SWR as well as on band performance.

Second loading coil which I made is here, along with the left out portion from the 500 gm enamelled copper wire which I had bought. This time I could make the coil in about 15 minutes.

Following up on the construction of 80m inverted V antenna with loading coils which had been posted yesterday. I have fixed both 2.25m insulated copper wire and 5.25m insulated copper wire to the loading coil. After that I scraped off the insulation at about 2 cm of terminal portion of the enamelled copper wire of the loading coil.

Same knife was used to remove the insulation from the terminal portion of the insulated copper wire. Then the ends of insulated copper wire and enamelled copper wire were twisted together and firmly fixed.

After repeating the procedure for all the four connections of the two coils, ends were secured with insulation tape.

Insulated copper wire lengths were checked so as to be almost equal on both sides of the antenna. Extra portion was folded back and pressed with pliers to mark the positions.

Now the two loading coils and two sets of antenna elements attached to either side are ready for mounting. Antenna elements have been made into coils and secured with tape so as prevent being entangled during storage. They will be uncoiled during mounting process.

Next step was to fix a piece of 1.25 inch PVC pipe between the 5.25m antenna elements. This was meant for fixing on to the mast. Insulations at the ends of the wires were removed for connection to the coaxial cable.

This cut end of 15m long RG213 cable does not have a connector. The inner conductor and outer shield were scraped with a knife to remove any dirt or oxide coating.

The outer shield was connected to one of the antenna elements fixed on a PVC pipe to hold it firm.

Connection of coax shield to the antenna wire was covered with insulation tape and the coax end fixed to the PVC pipe with the same tape to prevent movement once the antenna is mounted.

Central conductor of RG213 was then connected to the other half of the antenna.

The joint was further covered with insulation tape so the whole assembly was secure and ready for mounting.

Using a step ladder, I tied the piece of PVC pipe with antenna connected, to a fiberglass pole which was already having my 40-10m inverted V dipole at the top. Total height from the ground would be about 6m.

Tied a nylon wire to one end of the antenna and the other end to half of coconut shell to throw it over the terrace fence to get the antenna tip down to the garden! Coconut shell would not cause much damage even if it falls on something on the way.

Here you can see the other end of RG213 cable, upper end of an HLF 200 cable coming from the shack and an SO 239 barrel connector for joining the two together.

Now the two cables have been joined together using the SO 239 barrel connector as both cables have PL 259 connectors as the termination.

After a lot more effort, the antenna is now ready, with both ends tied on the garden fence with nylon ropes, at around 6 feet height.

Initial test on very low power at 3.6 MHz showed an SWR of about 4:1, not a happy situation. Tested near the lower end of the band and it was slightly higher. Checked near the upper end of the band and it was slightly lower, still beyond the tunable limit of the automatic internal tuner of my FT-710 radio.

Checked the SWR on 14.200 MHz as the design instruction by VU2XTO had mentioned that the 20m part has to be tuned to 1:1 SWR before adjusting the 80m part. To my pleasant surprise, I found an SWR of 1:1!

Checked near the upper end of the 20m band and the SWR was between 1.5 and 2, well within the tunable range of my FT-710 radio. I did check on 40m as well as someone on X (Twitter) had asked about the possibility working 40m. The SWR was higher than that noted on 80m.

Finally I checked near the lower end of the 20m band. That was also 1:1. Now I have a perfectly tuned antenna for 20m, that is first step success as per design! By the time I had finished the job, 80m net on 3.6 MHz had long been over and there were no stations to be heard on 80m. Today evening, I will test the performance of my new antenna on 20m as it resonates well for a large part of the 20m band without tuner. Tomorrow morning I will try to listen to 80m net at 7.15 am to see whether the reception is anyway better than my 40-10m inverted V dipole. After that I will embark on tuning the antenna for 80m. From the preliminary information which I have on the SWR pattern across the 80m band, I think I will have to lengthen the terminal 2m part. Actually VU2XTO had mentioned in his article that he ended up with 1.5m for resonance at 3.6 MHz. Let us see what happens in my case within a couple of days.

On band testing of the newly built loaded coil inverted V dipole antenna for 80m (VU2XTO design) continued in the evening. Excess RG213 cable was kept on the terrace in loops, thinking that coiling it might cause an ‘RF choking’ effect. By evening I could test the performance on 20m as the band opened up. I felt as if I was hearing stations better than my previous End Fed Half Wave Dipole Antenna which had to be grounded for connecting the loaded coil dipole antenna for 80m. Even though it was easily tuned to multiple frequencies on 20m with the built-in antenna tuner of FT-710, it seemed that the stations which I hear loud and clear were not hearing me. Power meter showed output power as before. Still I could work one contest station from Indonesia on 20m with 5,5 report.

I also checked reception on 80m with the help of my 40m friends VU2MIE (63.1 km) and VU2XPZ (127.7 km) just before 6 pm. I could hear VU2MIE who was nearer fairly well and VU2XPZ faintly, on 3.6 MHz. It seemed that the reception was better than on my 40-10m inverted V dipole antenna which was mounted at the apex of the mast while the 80m loaded coil antenna was mounted only half way up. Difference in reception between the two stations was expected from the distance and it was a bit early for good propagation on 80m.

The HLF 200 coax shield had been grounded near the entrance to the shack. That was removed first as I wanted to reduce the length of the redundant feedline. Then the barrel connector between HLF 200 and RG 213 was unscrewed and HLF 200 cable which was 10m long was removed from the feedline. What remained was 15m of RG 213 from the loaded coil dipole directly to the radio, a decrease in length of feedline by 10m and removal two additional joints in the circuit. On rechecking SWR it was found that SWR was very high on 80m band and around 2:1 in the 20m band. 20m could be tuned using the built-in automatic antenna tuner of the radio. Still, I could get a contact with KE5EE with 4,5 report and good report from VU2DK on 14.207 MHz in the evening. VU2DK had initially relayed my call to KE5EE. Later in the evening VU3CDK emailed me mentioning that my signal on 20m seemed better than before.

Got to work again on the loaded coil inverted V dipole antenna for 80m once again today morning. Initially I shortened the antenna elements on both ends by 20 cm and tested SWR. It was still very high. Then I folded back 50 cm on either side and tested again. It was still very high on 80m. SWR on 20m was still quite reasonable with about 1:1 at lower end of the band and about 2:1 at the upper end of the band.

Had a discussion with VU2XTO on 40m afterwards and he asked me to calculate the inductance of the coil and adjust the element lengths according to the calculated inductance. He also cautioned that if high power is delivered to the coil with a linear amplifier, it will heat up and melt the PVC former. VU2MSA who was also there during the discussion on band shared similar experience with a trap dipole for 80m heating up in the middle of a QSO on higher power. He also suggested that it is better to measure inductance with an LC meter, which I do not have! When I calculated the inductance using an online Coil Inductance Calculator, I found that the estimated inductance was only 52 microhenries instead of the 118 microhenries mentioned by VU2XTO in his article. Now I am in a fix. I have to either increase the length of the wires or make a new set of coils with higher inductance! A rough calculation tells me that if I am increasing the wire length, an increase of about 15 feet will be required and that will make the antenna unmountable in my restricted space! I have decided to get an LCR meter before proceeding further.

As I had mentioned in another video, I brought down the loaded coil 80m dipole antenna which did not resonate on 80m and checked the inductance of the loading coils with the newly bought LCR meter. As expected, the inductance was low, at about 62 microhenries, though it was a little more than the 52 microhenries I had calculated using an online calculator.

After some brainstorming sessions with my friend VU2XPZ, I decided to add additional turns of enamelled copper wire as a second layer over the existing coils. In between I did a few experiments with the coil and the LCR meter out of curiosity. This one was checking the two coils connected in series to check the inductance. As expected, it showed an inductance of 133.4 microhenries.

Next I checked the inductance of the remaining coil of enameled copper wire and found the inductance as 634 millihenries.

After that I added a layer of winding over the existing winding. As the windings were being joined at one end, I thought of winding the second layer in the opposite direction, presuming that current in both sets of coils will be in phase if I wind like that. Scraped the enamel off from a part of the wire and checked inductance and found it to be 198.3 millihenries.

Further checking was done after unwinding a few turns and scraping the enamel out in a new region. Inductance had come down to 143.8 millihenries.

In the next step, I separated the turns a bit to increase the spacing between them and rechecked and I got an inductance of 119.8 millihenries.

Followed the same type of trial and error methods for the second loading coil and finally got an inductance of 122.1 millihenries. I decided to accept that difference between the two coils as I was fed up of multiple trial and error adjustments spread over two days.

In between I did another experiment to relearn what I had learned at school days. With the LCR meter connected, I introduced one limb of iron pliers inside the PVC former of the loading coil. You can see that the inductance increased gradually as the ‘iron core’ was introduced, with maximum inductance of 173 millihenries when the core was fully in, only to return to baseline value when the core was withdrawn. Next step will be to put the coils back with antenna wires, mount it and test it, possibly tomorrow morning.

Mounted the revised 80m antenna with the new loading coils with inductance of about 122 millihenries each and checked the SWR on 80m. It was seen to be uniformly high across the 80m amateur radio band. This clip shows the test near the lower end of the 80m band.

Checked at the middle of 80m and it was high.

This test was at the higher end of the band, again showing high SWR.

Next I thought of looking at 20m band which was perfectly tuned with the previous loading coils. But the SWR has gone up on 20m, with about 5 at the lower end of the band.

It was higher when tested on 14.050 MHz.

Surprisingly, even though the SWR reading was in the region of 5, the automatic antenna tuner on FT-710 could tune it nicely to 1:1. As per the specification, the built-in automatic tuner of FT-710 can tune only SWR below 3.

Next I went back to the online calculator and after some trial and error, I noted that for an inductance of 122 microhenry in the loading coils, total antenna length has to be 44 feet and the distance from centre of the antenna to the center of the coil must be 16.4 feet. That means I have to reduce about 30cm from either side of the antenna as per the revised estimate. As I was working without the aid of a nanoVNA, (a miniature a handheld Vector Network Analyzer) which could tell the exact resonance frequency, I knew it will be tough to tune a loaded coil dipole antenna which has only a narrow bandwidth of 15 kHz. Checked after reducing 30 cm from either side and checked once again. Still there was no difference in the pattern of SWR across 80 and 20m bands.

As the SWR was high on 20m, I decided to try shortening the antenna elements from the feed point to the loading coils, which are meant for 20m. The SWR pattern was that it was higher at the upper end of the band than on the lower end of the band. Even at the lower end of the band, it was 5. That is why I thought of shortening the antenna. Trimmed nearly 10 cm from both sides of the elements for 20m and tested again. High SWR on 80m and almost same pattern of SWR on 20m. As before, the lower end of band can be tuned with the built-in automatic tuner of FT-710 as before, though mid segment of the 20m band with higher SWR cannot be tuned with it. So I am stuck again. Only option for me without a nanoVNA is to keep on pruning the 20m elements till it resonates. Incidentally, I found that the SWR is almost similar on 30m and 20m. Not sure whether there is any lead for me in that. May be the current resonance will be somewhere between 30m and 20m, in non-amateur segments.

Started working again on the loaded coil 80m dipole antenna today morning. You might wonder why only a little bit of work is done each day. The antenna trimming is not at the ends, it has to be done before the coils to adjust resonance for 20m. For that I have to untie the antenna ends and pull up the antenna elements back to the terrace. Then I have to remove the insulation from the end of the coil and separate the antenna elements. After this I have to trim the antenna element, clean the contacts and then re-attach to the coil. As the terrace becomes quite hot in the bright sunlight, I can’t work too long in this process. Today I trimmed off 20cm boldly from both sides, though it would be better to trim 10cm for a 20m antenna. As it is trimming and not folding back the ends, it is an irreversible process and if I end up at resonance above the band, I can’t go back quickly. I will have to add extra length of wire, with one more joint in an antenna already having several joints due to the coil made in two attempts.

Mounted the loaded coil 80m antenna back again and started checking the SWR on 20m. Checked at the lower end of the band and I was happy to find that it had come down from the previous 5 to around 4 this time on 14.010 MHz.

It was slightly higher at 14.100 MHz.

Almost same pattern was noted at 14.200 MHz.

SWR was nearly 5 at 14.330 MHz, near the upper end of 20m amateur radio band.

This time it tuned with the built-in automatic tuner of FT-710 at 14.200 MHz, which it had not done when the SWR was above 5 on the previous day.

It did tune at the upper end of the 20m band as well, even though the SWR was nearing 5. Tuned SWR was 1:1 across the whole 20m band. Checked SWR on 30m band and found it to be above 5. So the actual resonance of the antenna is between 30m and 20m amateur radio bands, this time nearer the lower end of the 20m band as can be seen from the pattern of SWR on the 20m band. Now at least I can operate on 20m with tuner. But the SWR on the whole 80m band continued to be high.

Decided to test out the performance on 20m band and I heard 8E3R from Indonesia, special event station of World Wide Award 2025. Made a quick call and received a 5,9 report at a distance of 2449.6 miles.

Checked the reception on reverse beacon network with CQ call on 20m and got spotted by VK6ANC at 3985 miles.

Came back and worked 8E3R once again, this time on CW, and received 5,9,9 report, followed by quick confirmation on their QRZ page as well. So I am happy that I have a functional 20m antenna now. I had pulled down my EFHW (End Fed Half Wave dipole antenna) for 20m when I mounted the loaded coil 80m dipole and was without 20m antenna for the past few days!

This is the video record of their CQ call in CW. You may note that the it is fairly fast, compared to my CW speed of just 10 wpm!

I could record their reply to me in CW as well. This is my first DX contact on CW in 2025. I am thankful to the operator at 8E3R for slowing down to my speed so that I could comfortably receive my signal report of 5,9,9.